Tyre manufacturing and recycling

Tyre manufacturing

From raw materials to tyres

For the manufacture of our tyres, we start with more than 200 raw materials, taking care to use more and more sustainable materials.

From these raw materials, the first step is to make materials with very specific mechanical and chemical properties. It is these properties that enable us to achieve good performance. In particular: good grip, good strength and good sustainability.

From these materials, we then design the composite product with two objectives:

1 - To minimise the amount of material used

Because the less material we use, the more we limit the impact of the tyre during its entyre lifecycle.

2 - Obtain maximum performance

The design of our tyres consists of assembling these materials in the most judicious way possible to make them work at their best intrinsic performance.

Optimisation of environmental impact and working conditions

While aiming at performance, our industrial production system is organised in such a way as to :

- Optimise the environmental impact Our ambition is to achieve carbon neutrality across the production base by 2050. We have made significant progress since 2010. Our 2030 target was approved by SBTi (Science-based targets) as ambitious and consistent with the goals of the Paris Agreement, and has since made even more ambitious.

- Optimise working conditions in order to obtain a good quality of life at work for MICHELIN staff.

A product with identical performance across countries

Our industrial process allows us to reproduce products identically on an international scale. Thus, a MICHELIN tyre has exactly the same level of performance whether it is manufactured in the United States, China or Europe.

The steps of the tyre making process

1- Understanding through research

We study peoples' tyre usage and driving habits to make sure our tyres meet everyone's needs.

2- Developing and mixing materials

Over 200 ingredients go into a tyre. They play vital roles in safety, fuel efficiency, performance and eco-friendliness. Their percentage varies according to the type of tyre to be manufactured.

These components fall into five groups:

- Natural rubber: the main component of the tread layers

- Synthetic rubber: part of the treads of car, van and 4x4 tyres. Research is underway to develop synthetic rubber (which is essential to achieve the targeted performance) so that it is made from more sustainable materials than oil or gas.

- Carbon black and silica: used as a reinforcing agent to improve durability. These components can be recycled. They can be processed and reused at the end of a tyre's life to make new tyres.

- Metallic and textile reinforcement cables: the "skeleton" of the tyre, forming the geometric shape and providing rigidity. Metal can also be recycled and research is underway to investigate the reuse of some textiles, originating from consumer products other than tyres, for the manufacture of new tyres.

- Numerous chemical agents: for unique properties like low rolling resistance or ultra-high grip

3- Designing

We use simulations to test and select the best tyre concepts to be developed. The difficulty lies in minimising the amount of material to meet the performance criteria. These simulations allow us to predict the performance which will then be confirmed by tests.

4- Manufacturing

We manufacture and reproduce each tyre in the most optimised designs possible with an optimum level of performance for both the product and the economic aspect.

5- Quality control

Quality control is not an end step. We measure quality throughout the entyre process.

Quality must be respected at every stage: design, manufacturing and distribution

What is the structure of a tyre?

The typical radial tyre consists of nine main parts.

1- Inner liner:

An airtight layer of synthetic rubber to ensure airtightness.

2- Carcass Ply:

The layer above the inner liner, consisting of thin textile fiber cords (or cables) bonded into the rubber.

3- Lower bead area:

This is where the rubber tyre grips the metal rim. The power from the engine and braking effort is transmitted from the rim of the tyre to the contact area with the road's surface.

4. Beads:

They clamp firmly against the tyre’s rim to ensure an airtight fit and keep the tyre properly seated on the rim.

5- Sidewall:

It protects the side of the tyre from impact with curbs and the road and also features the specific MICHELIN design. Important details about the tyre are written on the sidewall, such as tyre size and speed rating.

6- Casing ply:

It largely determines the strength of the tyre. It's made up of very fine, resistant steel cords bonded into the rubber. It's also flexible enough to absorb deformations caused by bumps, potholes and other obstacles in the road.

7- Cap ply (or "zero degree" belt):

This important safety layer helps maintain the shape of the tyre when driving fast. To prevent centrifugal stretching of the tyre, reinforced nylon based cords are embedded in a layer of rubber and placed around the circumference of the tyre.

8- Crown Plies (or belts):

They provide the rigid base for the tread.

9- Tread:

This is the part that is in contact with the road. It provides traction and turning grip for the tyre and is designed to resist wear, abrasion and heat. Its sculpture is designed for very precise functions (grip, water evacuation, etc.) and also includes a design dimension specific to Michelin.

Tyre recycling

During the initial design phase, the global impact of the tyre is taken into account to minimize it, including raw materials, manufacturing, transport, usage and end-of-life. Each step is carefully analyze to improve the global impact.

As we will explain here, the environmental impact is taken into account in the manufacture of our tyres, and this under different aspects, not only that of tyre recycling.

A limitation of the raw materials used

A tyre is capable of withstanding enormous stresses. Indeed, the 35 kg of tyres fitted to a vehicle can carry 2.5 tons over several tens of thousands of kilometres in sometimes extreme weather conditions ranging from -20°C to over 40°C.

In order to achieve this performance and at the same time protect the environment, we use a minimum amount of material to manufacture our tyres.

How is limiting material beneficial to the environment?

- The lighter a tyre is, the lowest is the dissipation of energy needed during rolling. This means less fuel consumption o fhte vehicle, less CO₂ emissions.

- The less material there is, the less resources we have to extract from the planet, preserving natural resources.

- Using less materials means also to reduce the amount of materials that are transported to the manufacturing plant, so less energy needed and less CO₂ emissions from the transport.

Performance made to last

MICHELIN tyres are designed to perform until the last kilometer, i.e. until the legal wear indicators are reached.

Our know-how allows us to ensure an excellent level of performance until this limit is reached, thus avoiding premature tyre replacement.

By using our tyres up to this limit instead of replacing them too early, you reduce the environmental impact while saving money and keeping your tyres performing well.

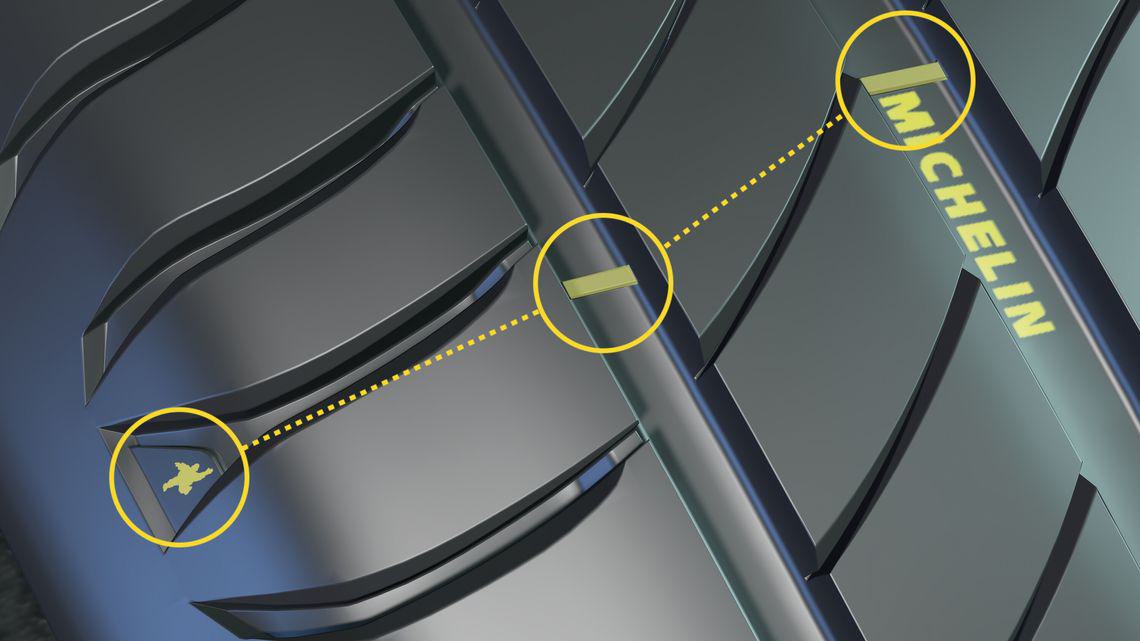

Our tyres show the position of the wear indicators with little Michelin Man markings, making it easier to check the level of tyre wear.

But our thinking on limiting environmental impact goes beyond simply limiting raw materials and tyre longevity. It also leads us to explore new ways of recycling.

How can the same performance be maintained using recycled materials?

This is one of the recycling options we are exploring. But it's not just about recycling components from other tyres at the end of their life to make new ones. We are also thinking about recycling components from products as far removed from tyres as plastic bottles, for example.

How can other products be made from used tyre components?

This other recycling option concerns the manufacture of products for uses other than roads, such as tennis courts.

The aim is that materials from used tyres can find a second life in a form other than that of a tyre within the framework of a relevant and compatible reuse.

Where to dispose of tyres when they are worn out?

Tyre recovery: The easy way is to bring them to a local dealer.

Michelin's partner companies are responsible for collecting used tyres for recycling. Through this process, we can recover pieces of tyres to turn them into valuable materials that can be used to manufacture new tyres.

In France, for example, waste collection sites transport tyres to centres responsible for redirecting them to recycling channels. The same process applies in most of the world’s countries.